Features

The product turned out to be extremely difficult to use:

Develop, install, and debug a packaging line

In addition to the packaging itself, the client needed:

- pre-mix several components;

- grind the resulting mixture to a homogeneous state before packaging;

- and at the same time, minimize dust dispersion as much as possible.

Decision from OMELA

We have developed and designed an anti-dust line, combining the processes of mixing, crushing, and packaging in a single technological solution.

Line structure:

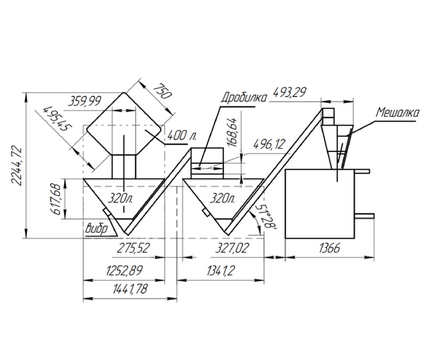

- Drunken barrel mixer

- Cubic shape, with an offset axis of rotation.

- Ensures high-quality and uniform mixing of all components.

- Unloading mechanism

- The mixer is mounted on guides and, after completing the cycle, moves onto the loading conveyor, discharging the entire batch of product.

- First screw conveyor

- Moves the product through the crusher, feeding it in portions, which ensures effective grinding and prevents the formation of lumps.

- Second accumulator conveyor

- Serves as a buffer between the crusher and the packaging area.

- Equipped with vibration motors that prevent product from sticking to the walls.

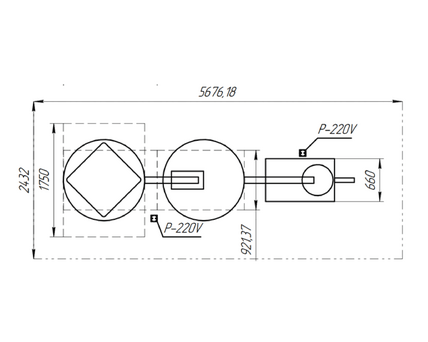

- Semi-automatic filling machine for valve bags

- Equipped with a built-in mixer in the hopper, which is especially important for difficult-to-pour mixtures.

- Ensures accurate dosing of 5.5 kg into each bag.

Additional features:

- Anti-dust design: all sections of the line were designed to minimize dusting.

- Rotary sensors: special models were selected that are capable of stable operation in dusty conditions for automation of feeding and packaging.

- Vibration motors: installed on conveyors, they ensure stable feeding and prevent product sticking.

Resultat:

- The client received a comprehensive, individually designed solution covering all stages

- from mixture preparation to packaging.

- The line works steadily with one of the most capricious products in terms of its properties.

- The entire process is organized taking into account the requirements for cleanliness and safety in production.