Client:

A manufacturing company launching a new line of instant soups, supported by a USAID grant.

Task:

To develop, supply and set up a packaging line for packing instant soups into a doy-pak type bag. The peculiarity of the task is that the product consists of several components (vegetables, meat, broth) (about 20 different combinations), each of which must be dosed separately with high precision. The package must be hermetically sealed after dosing the hot broth.

Complexities of the project:

- Product heterogeneity: a mixture of cooked vegetables and meat with different physical and mechanical properties (stickiness, different fractions, weight, moisture).

- High dosing accuracy: it was necessary to ensure a stable weight of each component in each package.

- Hot broth: quick and safe liquid refilling into a relatively small package was required.

- Docking of equipment from different manufacturers: Chinese dispensers and conveyors, Ukrainian packaging machine.

- Tight budget constraints: the project had to fit within the scope of the USAID grant

OMELA solution:

OMELA undertook the complete turnkey implementation of the project - from conceptualization to line start-up and integration.

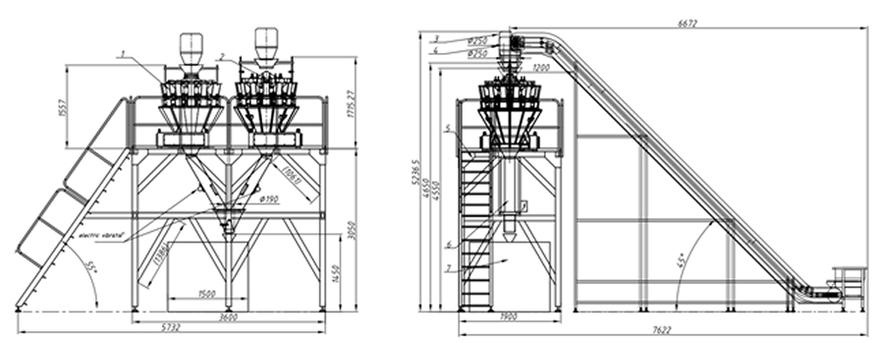

Line composition:

- Vibrating multihead weigher - vegetable filling.

- Screw multihead weigher - filling of meat components.

- Two loading conveyors - product feeding to the metering units.

- Work platform - for positioning of the pipettes and access to maintenance.

- Rotary packaging machine (doy-pak) - dosing, hot broth dosing, sealing.

- Additional equipment - broth pump, control valve, communications (air, power, etc.).

Features of realization:

- OMELA integrated equipment from Chinese and Ukrainian partners, ensuring synchronized operation of all units.

- Each component of the line was carefully tuned to the product properties.

- OMELA adapted the design of the equipment during the production process according to the customer's wishes (movement of steps, access to nodes, etc.).

- OMELA specialists installed and tied the equipment and ensured the installation of all communications.

Result:

- Reliable and flexible packaging line adapted to complex products.

- Precise dosage of each component ensures recipe stability.

- The line is successfully commissioned and operating within the customer's new production site.

- The client received a ready-made solution that fully complies with the terms of the grant and its own requirements.

The new solution allowed the client to reduce packaging costs by using modern technologies and materials.

The project was implemented with the support of USAID